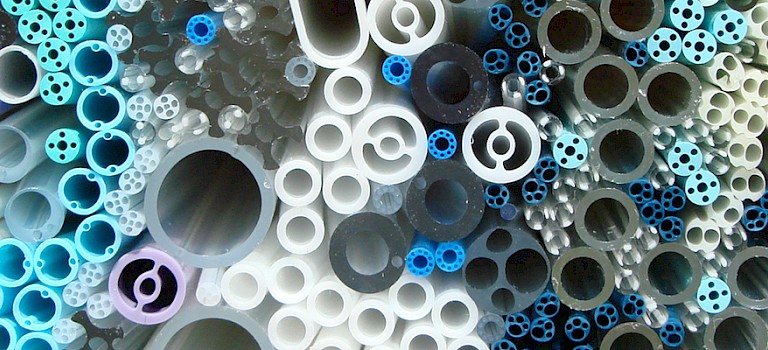

Come to us with your toughest challenges in custom medical tubing. We'll help make the impossible possible.

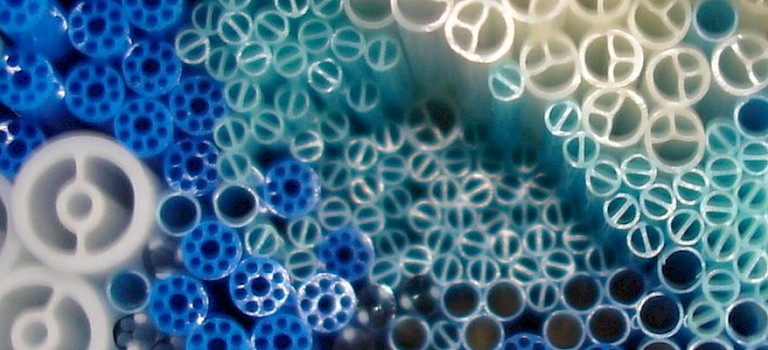

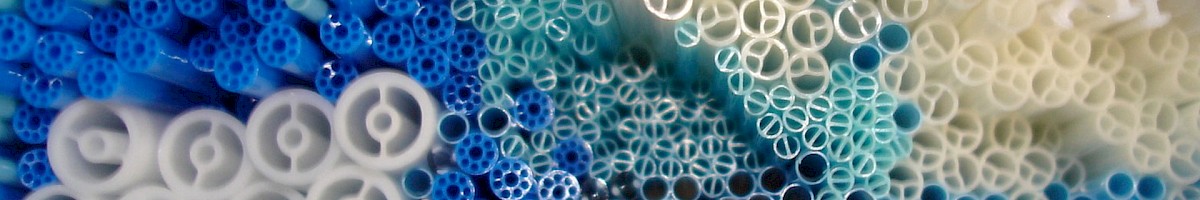

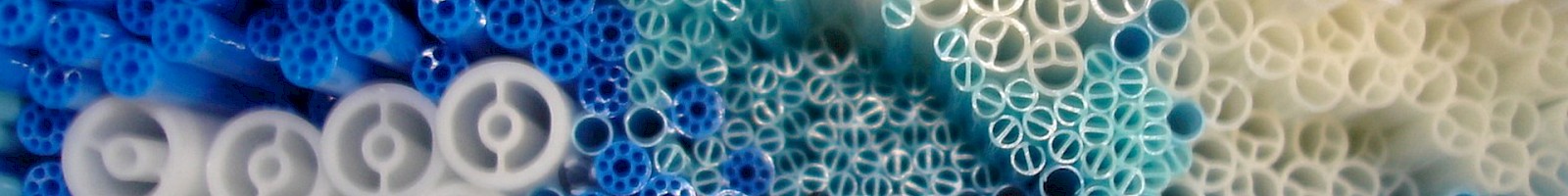

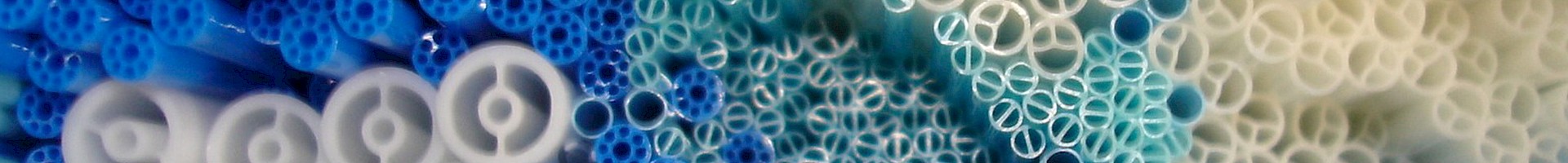

With our proprietary processes and tools, Microspec has earned a global reputation for extruding some of the smallest, most complex and tightly toleranced medical parts in the industry. We extrude custom medical parts with outside diameters (ODs) from 0.003 inch to approximately 1.00 inch (0.076 mm to 25.4 mm) in any quantity, from experimental to commercial runs and from small development lots to millions of parts per year.

- Our hand-picked, highly trained and experienced team works collaboratively with you to meet your specifications. Find out more about Our People.

- Since 1989, Microspec has led the way in research, engineering and extrusion of advanced medical tubing. Find out more about Our History of excellence.

- We operate as a trusted extension of your own product development team with the same commitment to success. Find out more about Our Customer Focus.

- At Microspec, research, process development, tooling and extrusion of custom medical tubing stay entirely in-house. As a result, we’re more agile and adaptive to change and have tighter control over the finished product. Find out more about Our Facilities.

- We value our people, their knowledge and their experience. Microspec continues to grow as we serve some of the largest suppliers of medical devices in the world. Find out about Careers and Internship Opportunities at Microspec.