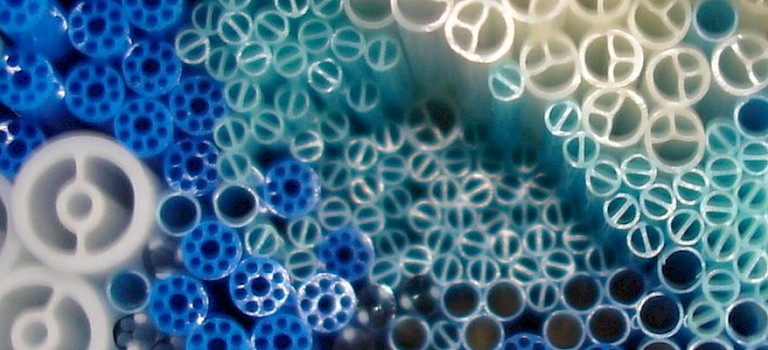

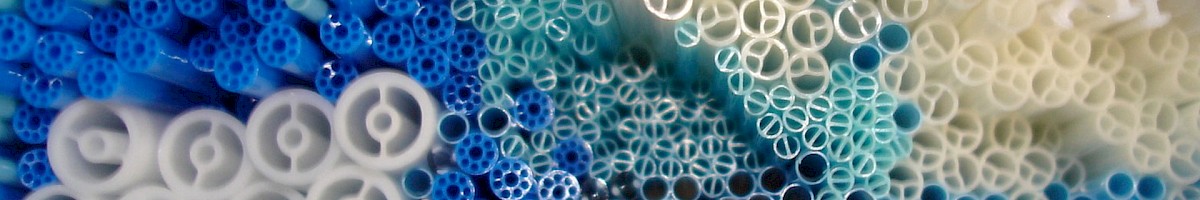

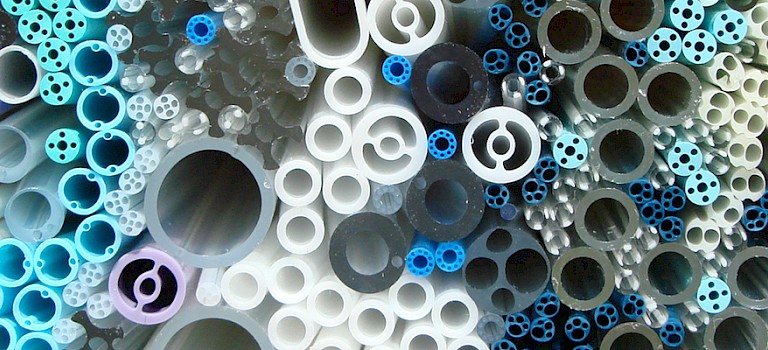

From concept to prototype to commercial run: We extrude custom medical tubing. We do it exclusively and we do it right.

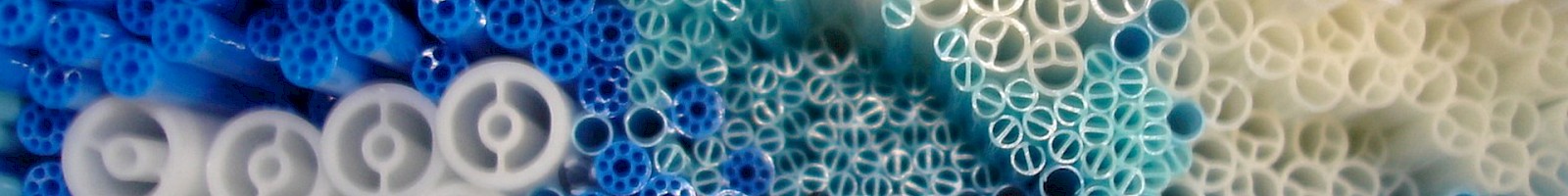

Our customers require some of the smallest and most complex tubing in the medical device industry, with some of the tightest tolerances. As a result, every extrusion technician at Microspec works to a level of precision that is measured in thousandths of an inch. We know that someone's life may depend on the medical device that you've developed.

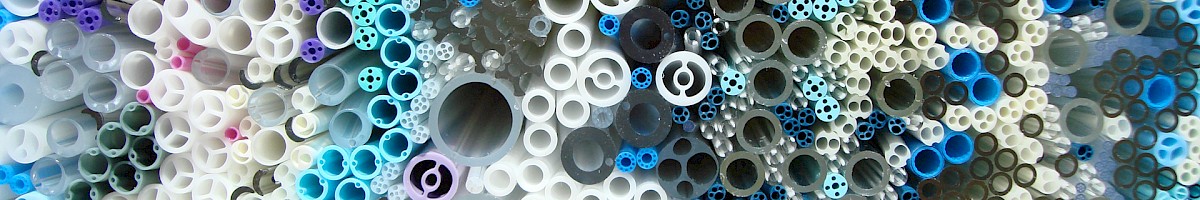

Working as an extension of your own product development team, we extrude experimental and commercial runs of advanced medical tubing using our own proprietary extrusion processes and tools. We are constantly improving our extrusion operations through initiatives like team problem solving, Lean manufacturing and Good Manufacturing Practices.

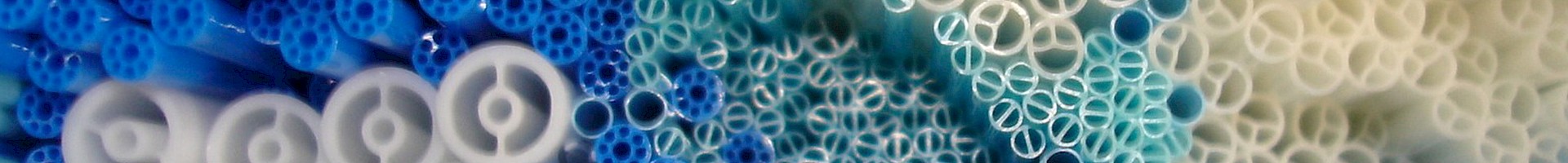

Because manufacturing, tooling and engineering are all handled in house, we're more agile and adaptive to change and have tighter control over the finished product.

Our quality systems ensure that everyone at Microspec operates with the same concern for quality. We make sure that only high quality tubing goes out the door.