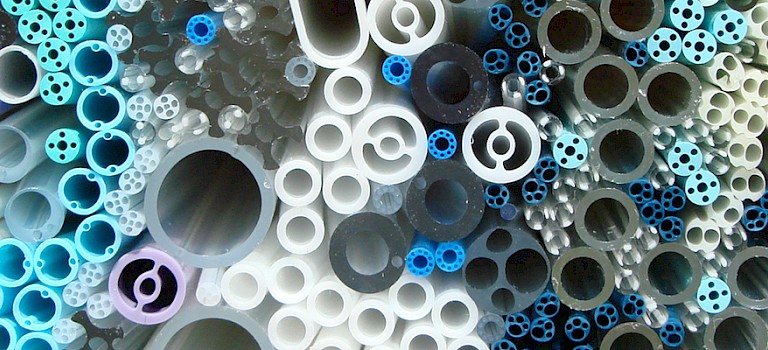

Everyone at Microspec is responsible for the quality of the custom medical tubing we extrude. Because the extrusion cycle remains in house, we have tighter control over the outcome.

Your custom medical tubing is evaluated:

- On the production floor

- In our quality control room

- At the start of, during and after each run

- Before shipment

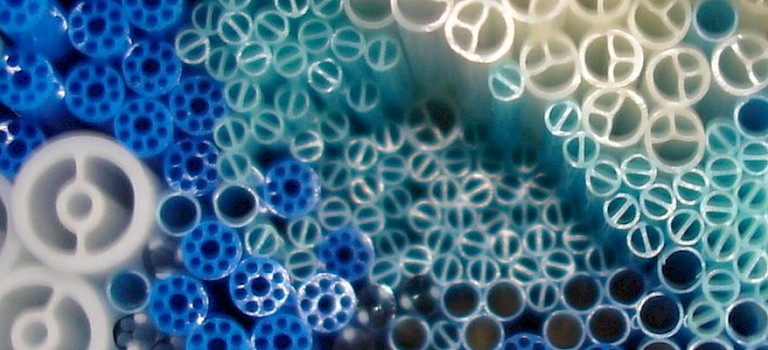

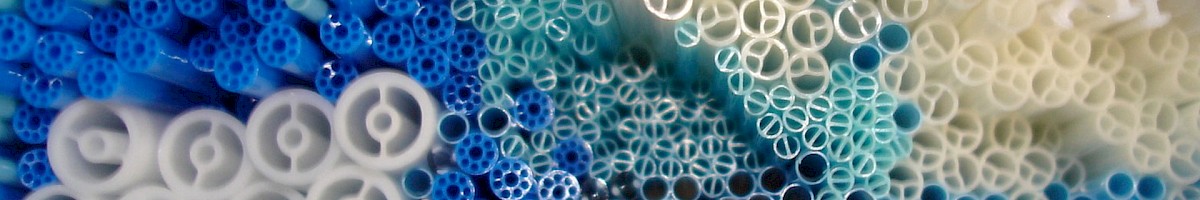

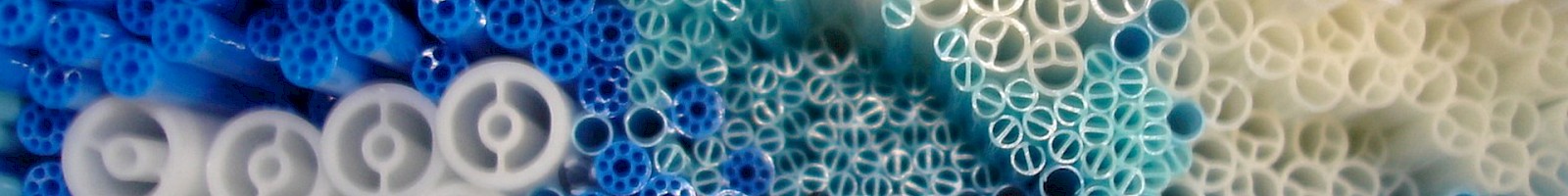

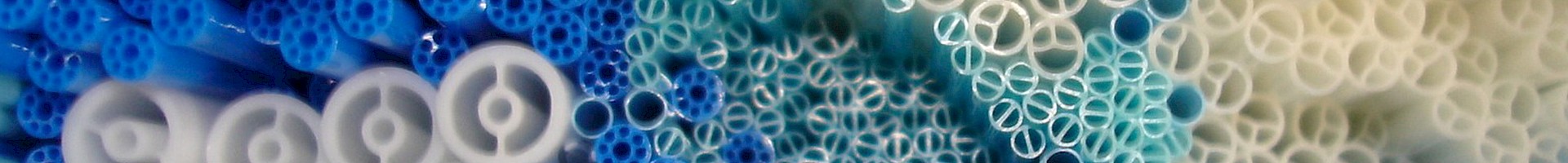

We use the latest inspection techniques including lasers and highly precise electronic microscopes. Among other calculations, we measure outside and inside diameters (OD and ID), number of lumens, wall thickness and profile against your specifications.

We're dedicated to continual improvement, as demonstrated by our ISO 13485-2016 certification, Lean manufacturing initiative and Good Manufacturing Practices.

Quality begins with training. Together, our quality staff has more than 50 years of experience in the medical device and extrusion industries. Each quality inspector undergoes training in Microspec’s rigorous standards and procedures for custom medical tubing.

We welcome customer audits.