At Microspec Corporation, research, process development, tooling and extrusion of custom medical tubing stay entirely in-house. As a result, we’re more agile and adaptive to change and have tighter control over the finished product.

In Peterborough, New Hampshire, our over 40,000 square foot facility includes a fully equipped machine shop for developing custom tools.

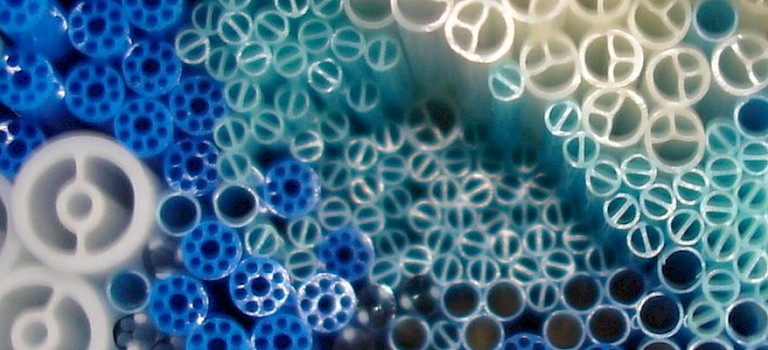

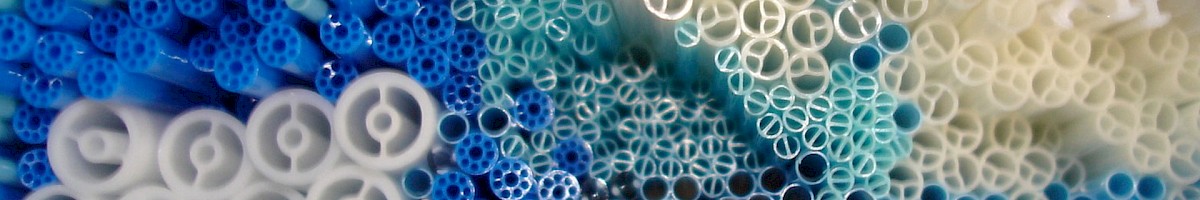

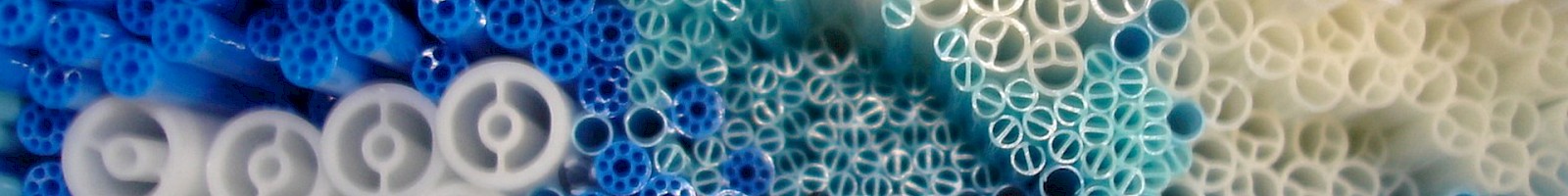

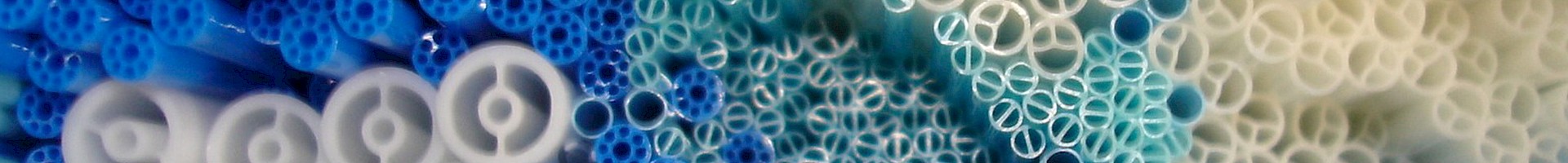

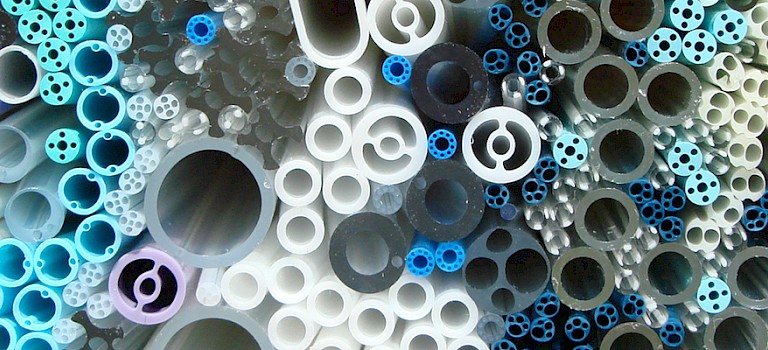

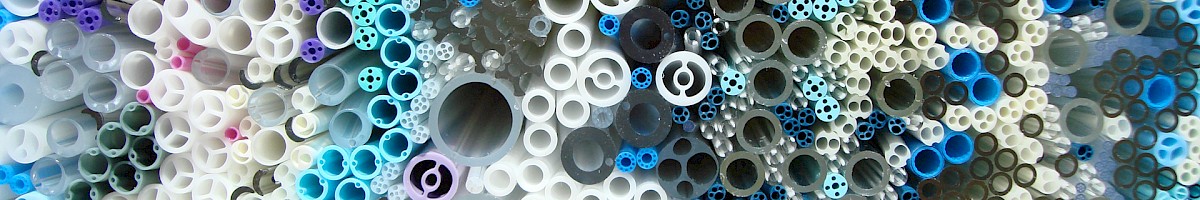

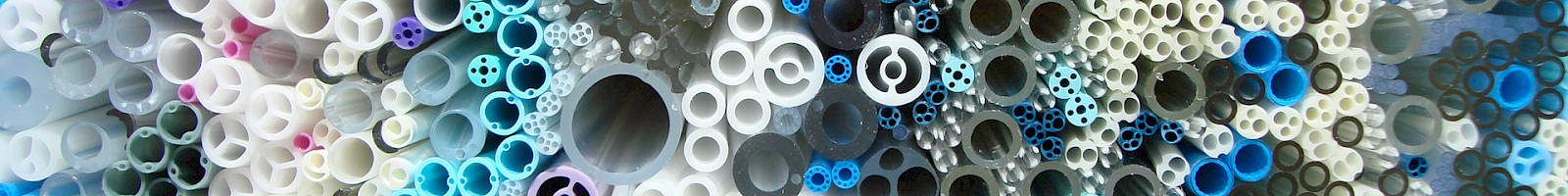

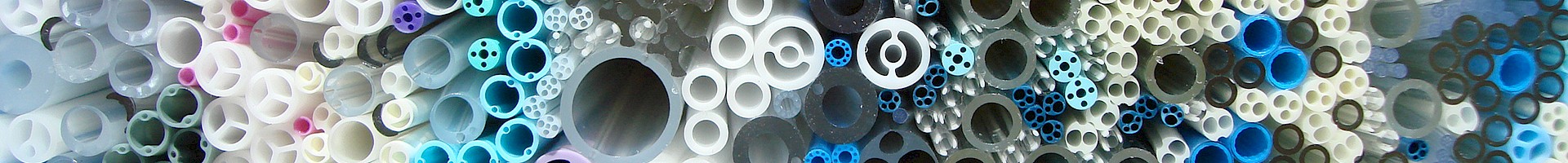

Microspec customers are among the foremost suppliers of medical devices in the world. The custom medical tubing that Microspec extrudes for them is among the smallest and most complex in the industry, with some of the tightest tolerances. We specialize exclusively in advanced medical tubing.

Manufacturing Area

- Over 20 extrusion lines, including co-extrusion, tri-extrusion, and intermittent lines

- Climate controlled warehouse

- Controlled manufacturing environment

- Flexible packaging options to accommodate customer specifications

- Kanban programs available

Extrusion Capabilities

- Bump tubing, co- and tri-extrusions, micro-extrusions, multi-layered tubing, multi-lumen tubing, profile extrusions, over extrusions, coated wire, balloon tubing, fully encapsulated stripes, ribbon extrusions, intermittent extrusions, and new concepts.

- Most thermoplastic elastomers and engineering resins, including fluoropolymers and custom formulations

- Small prototype lots to high-volume commercial runs

Technical Expertise

- Specialization in extrusions with ODs 0.003 inch to approximately 1.00 inch (0.076 mm to 25.4 mm)

- Annealing services

- Raw material and product testing, including burst and tensile

- Product validation services, including OQ, PQ, and PPAP

Exceptional Customer Experience

- Close working relationships with our customers

- Regular, detailed updates from receipt of order to shipment of product

- Technical advice is part of our extrusion service

Our Machine Shop

- Contains specialized equipment and software, including MasterCAM and wire EDM (electrical discharge machine)

- Designs and fabricates our proprietary tooling

- Maintains our extrusion equipment

Our Quality Control Area

- Utilizes automated inspection routines to improve measurement repeatability and reproducibility using state-of-the-art vision systems

- Utilizes laser gauging equipment

- Evaluates tubing at the start of, during, and after each run, and before shipment

- Proactively collaborates with our customer’s quality team to align inspection methods