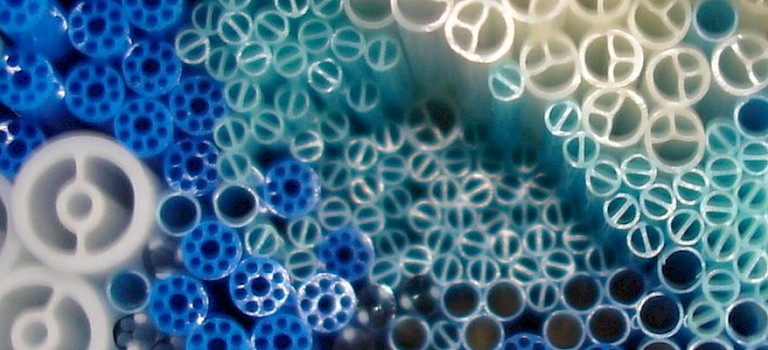

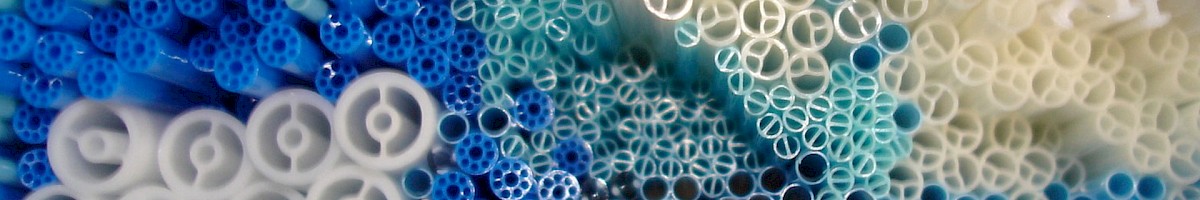

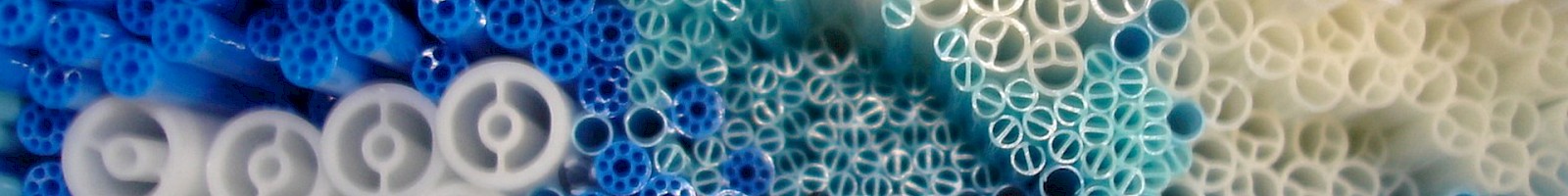

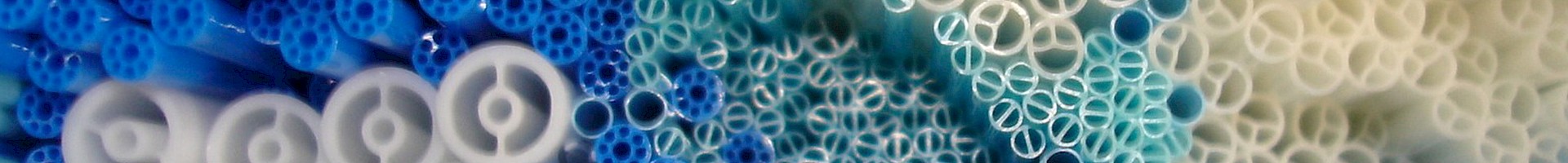

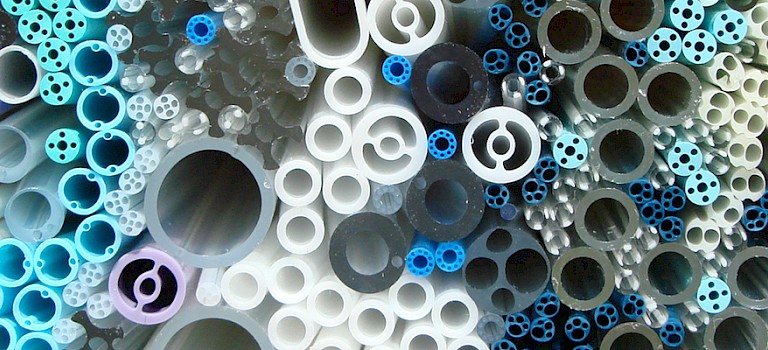

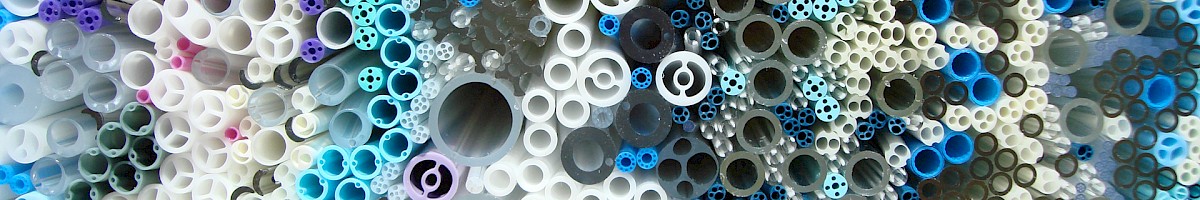

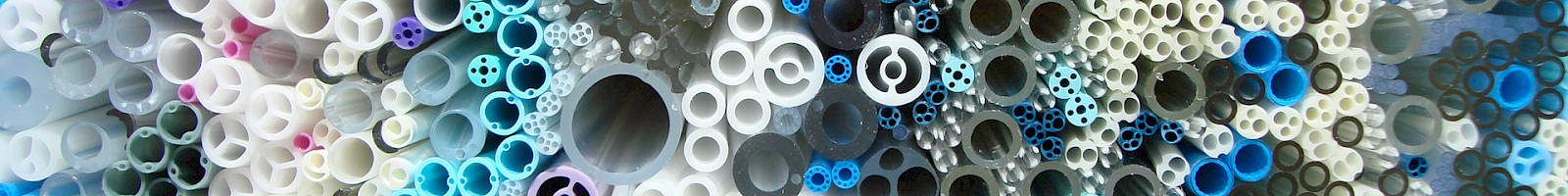

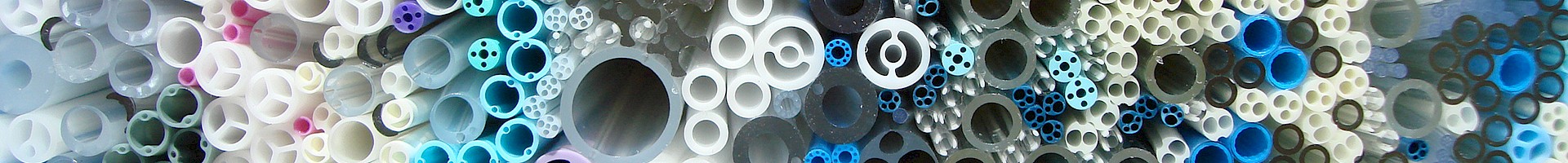

Companies around the world depend on Microspec to extrude custom bump tubing, co-extrusions, micro-extrusions, multi-lumen tubing, profile extrusions and coated wire. We specialize in medical tubing with an outside diameter (OD) from 0.004 inch to 0.450 inch (0.1 mm to 10 mm), using polyurethanes, nylons, engineering resins and other materials, including custom and proprietary formulations. We are the recognized industry leader in extruding vascular bump tubing.

We understand the relationship between:

- Material properties, such as hardness, heat distortion, tensile strength and elongation

- Process conditions, such as temperature, rate of cooling, flow rate and pressure

- Extruder capabilities and tooling

Our extrusion technicians are globally respected specialists in complex medical tubing. They average 11 years of experience in medical extrusion. We draw on that experience to keep ahead of the trends, reduce your risks and help bring your medical device to the marketplace.

Our production area contains pellet dryers, seven dedicated extruders, precise cutting tools and testing equipment. We welcome both prototype and high-volume commercial runs.

Glossary Of Terms

extruder

Equipment for melting, pressurizing and homogenizing plastics by means of a rotating screw. Different configurations are possible; the most simple one is a single screw extruder mainly used for conversion processes like profile extrusion.