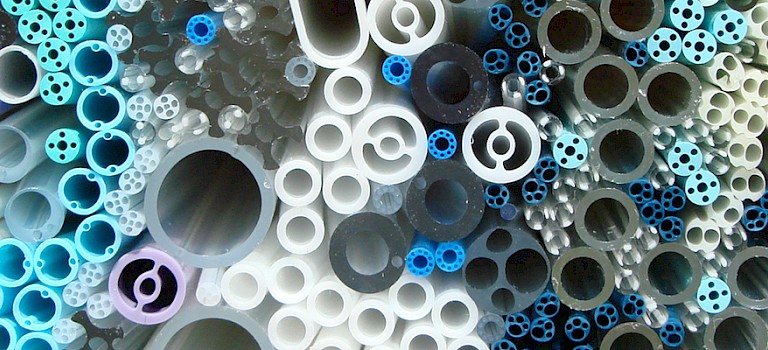

Engineering resins are a group of plastic materials that combine great strength with light weight over a wide range of conditions. They are usually chosen for one or more enhanced physical properties; for example, polycarbonate (PC) is known for its impact resistance and polybutylene theraphthalate (PBT) for its dimensional stability. Other characteristics of some engineering resins are high heat resistance, rigidity and chemical stability. Most engineering resins have improved performance at temperatures above 275°F (135°C).

The term "engineering resin" usually refers to thermoplastic materials. Thermoplastics are elastic and flexible above each resin's specific glass transition temperature. Depending on the temperature, most thermoplastics have a crystalline region (giving it strength and rigidity) and an amorphous region (giving it elasticity). Thermoplastics that do not crystallize are called "amorphous" plastics and are most often used in applications where clarity is important.

Glossary Of Terms

glass transition temperature

The lowest temperature at which a polymer can be considered softened and possibly flowable. The temperature at which amorphous polymers undergo a second order phase transition from a rubbery, viscous amorphous solid to a brittle glassy amorphous solid.

| Property | Measure Low | Measure High |

|---|---|---|

| Hardness | Somewhat rigid | Very rigid |

| Vicat Softening Point | 286°F (141°C) | 426°F (219°C) |

| Tensile strength | 10000 psi (68.9 MPa) | 16000 psi (110.3 MPa) |

| Elongation at break | 50% | 150% |

| Biocompatibility | Not suitable for remaining in the body as long as 30 days | |

| Sterilization | Ethylene oxide (EtO) Gamma and E-beam radiation (limited) Steam autoclaving Vaporized hydrogen peroxide |

|

| Trade Names | Polybutylene Teraphthalate Polycarbonbonate Polyetheretherketone Polyetherimide Polysulfone |

|