What is the smallest sized tube Microspec extrudes?

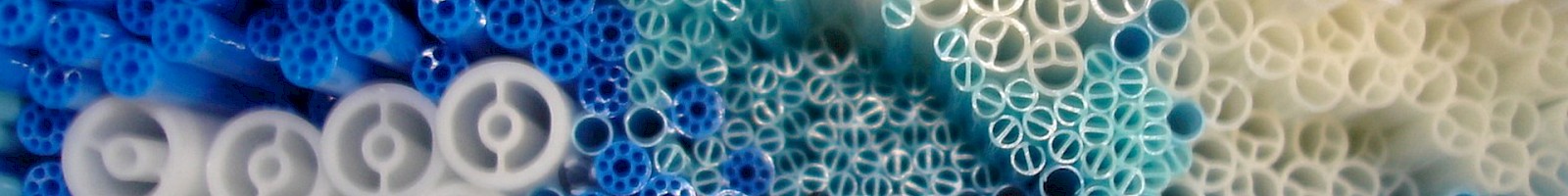

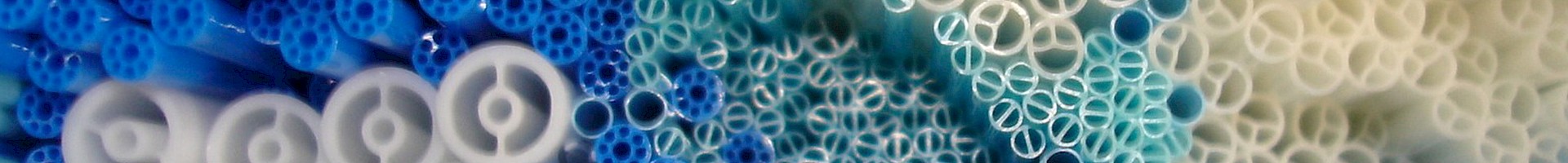

Microspec has earned a global reputation for extruding the smallest, most complex medical tubing in the industry, with the tightest tolerances. We have extruded tubing with an outside diameter as small as 0.004 inch (0.1 mm) and multi-lumen extrusions as small as 0.012 inch (0.305 mm). In addition to micro-sized multi-lumen extrusions, Microspec extrudes multi-lumen bump tubing as small as 1.9 French. We are at the forefront of technology to achieve even smaller diameters.

What is the largest sized tube Microspec extrudes?

Microspec extrudes custom medical tubing with an OD from 0.004 inch to 0.450 inch (0.1 mm to 10 mm). Most of our tubing is below 0.125 inches (3.2 mm).

What materials does Microspec specialize in?

Microspec uses polyurethanes, nylons, engineering resins and other materials, including custom and proprietary formulations provided by our customers. Since 1989, we have continued at the forefront of research into extrusion materials, concentrating exclusively on medical tubing. We work objectively with all material vendors to determine if their materials might be suitable for advanced medical tubing. We alert you when new sources and new extrusion materials come onto the market.

What is the smallest/largest sized run Microspec can deliver?

Microspec handles any size run from small development lots to millions of tubes. In Peterborough, New Hampshire, our 21,500 square foot facility includes:

- Fifteen extruders for prototype and high-volume commercial runs

- A fully equipped machine shop for developing custom tools

- Research, engineering and development space with two dedicated extruders

We have the capacity and physical space to expand to meet the needs of our customers.

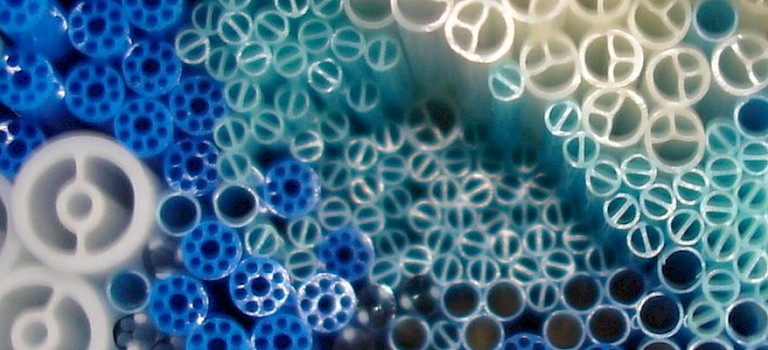

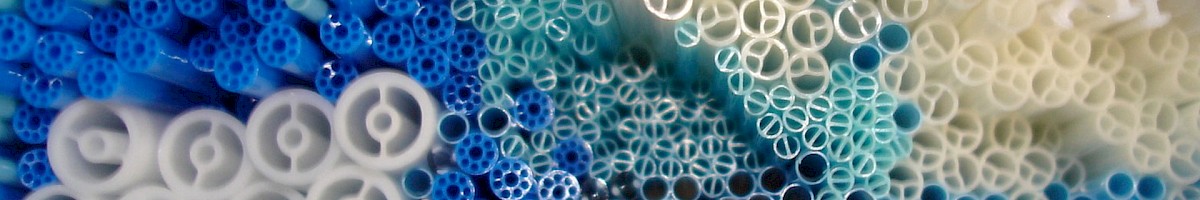

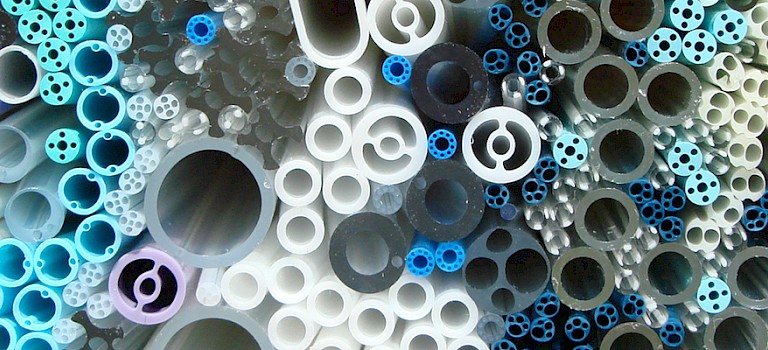

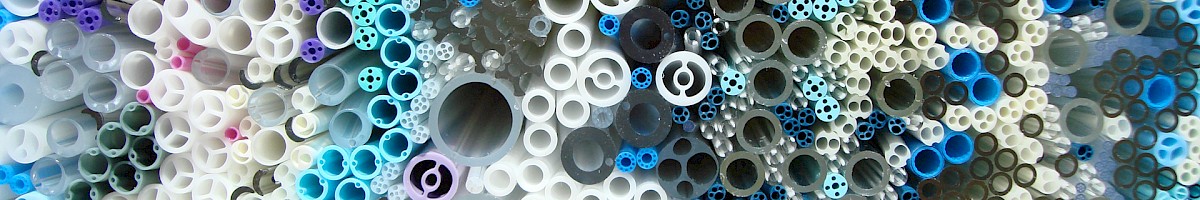

What types of extrusions does Microspec specialize in?

Companies around the world depend on Microspec to extrude custom bump tubing, co-extrusions, micro-extrusions, multi-lumen tubing, profile extrusions and coated wire. Microspec’s people were instrumental in the development of co-extrusion technology. We are recognized industry leaders in extruding multi-lumen bump tubing and vascular bump tubing.

Are any types of extrusions or materials outside Microspec’s area of interest?

Microspec continually experiments with new profiles, new materials, extrusion processes and equipment.

Does Microspec extrude prototypes?

Yes. We welcome both prototype and high-volume commercial runs. Through skillful process and tool design, Microspec increases the quality and functionality of complex medical tubing and simplifies your device assembly. We keep ahead of advances in the extrusion industry, reducing your risks and helping you move your medical device efficiently from laboratory to marketplace.

What information does Microspec need from me, the customer?

We would appreciate drawings and specifications. We would also like information on:

- The materials you’re considering and why you prefer them

- What characteristics you most want in your tubing

- What function(s) the tubing must perform

- What dimensions you’re considering for OD, ID, lumens, web thickness, etc.

- Your time frame

How quickly can Microspec deliver on a prototype?

The more complex an extrusion, the more time it takes to meet your exact specifications. Microspec specializes in custom medical tubing, and we have a globally recognized history of success. Because extrusion engineering, tooling and operations stay entirely within Microspec, modifications are more efficient—and more precise—at every stage. We have earned a global reputation for technical depth, creativity and ability to scale to commercialization.

How long has Microspec been in business?

Microspec began in 1989 without its own equipment, a permanent home or even a customer—but with a very clear vision: to become a driving force for innovation in custom medical extrusion. Now Microspec is an industry leader with a global reputation for innovation, quality and willingness to accept challenges.

We’re small enough for every employee to take personal responsibility for your custom medical tubing. We’re large enough to handle the most demanding commercial runs. We have structured our business for growth and continuous improvement. We are already positioned to triple our business. With extremely low turnover, we have established a group of extrusion technicians, extrusion engineers, quality assurance personnel, machinists and support staff with more than 12 decades of experience in the extrusion and medical device industry. Our cumulative knowledge gives us the power to innovate.

Can I get a catalog or product list?

We are a custom manufacturer and do not have a catalog or product list. But we would be happy to send you samples or answer any questions you have.

Can Microspec help with material selection or product development?

We’ll apply our specialized knowledge of materials, equipment, processes and tooling to solve your most challenging problems in advanced medical tubing. We’ll help you find the information you need and we’ll help you interpret it. Our customers depend on our knowledge of existing technology and our willingness to innovate.