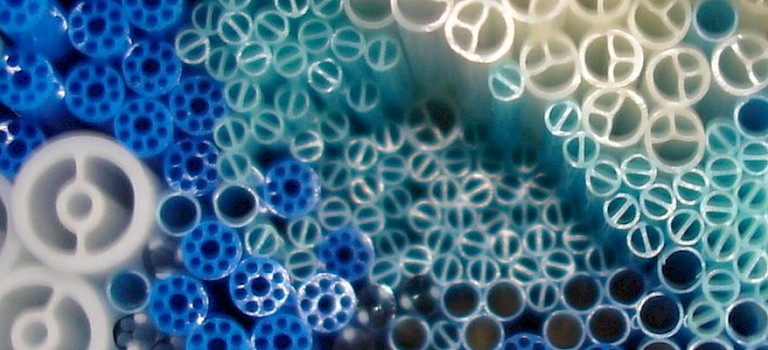

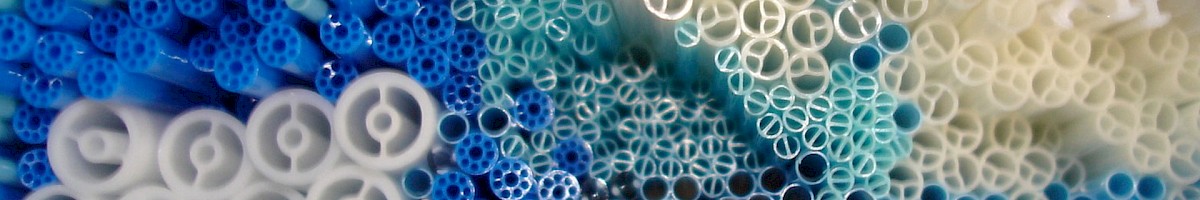

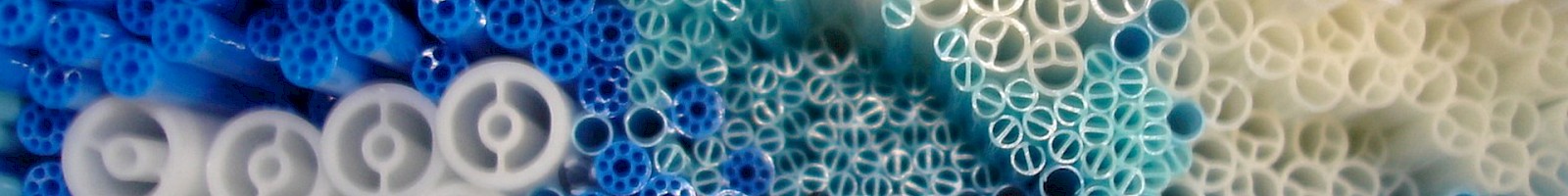

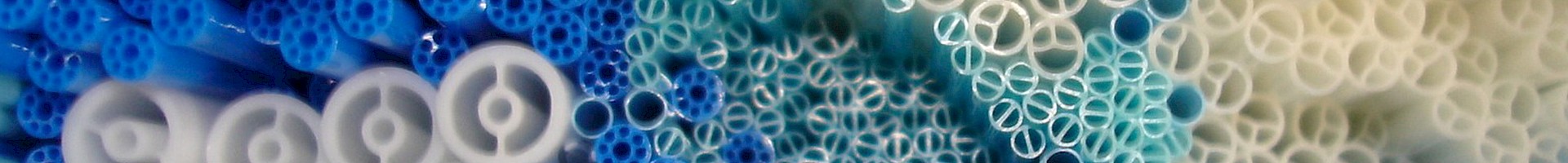

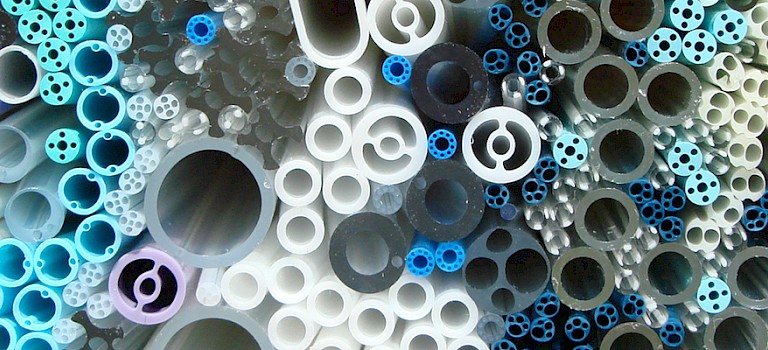

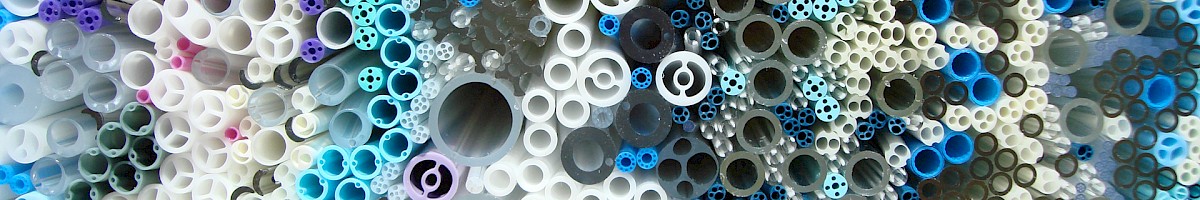

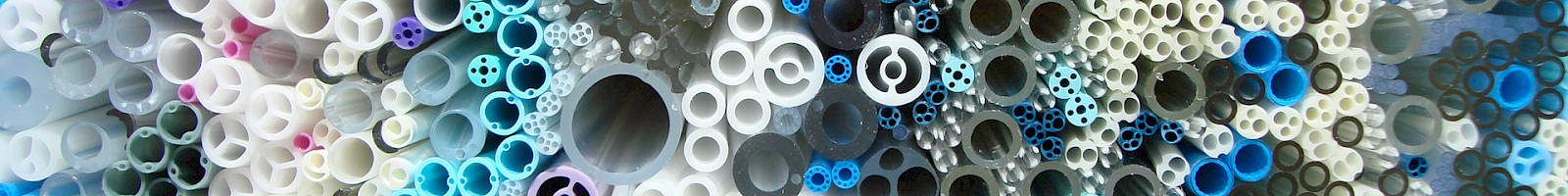

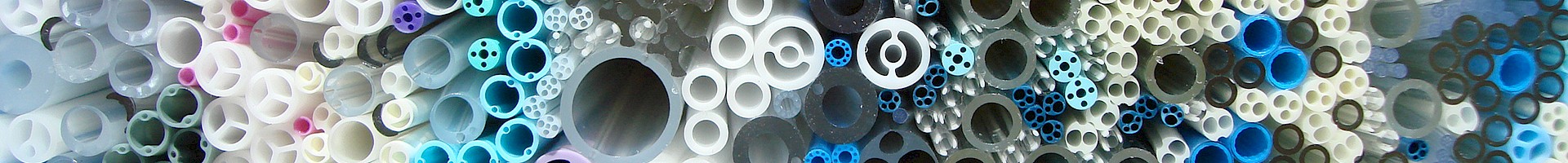

To extrude your complex medical tubing, we design and engineer our own proprietary tooling. Because Microspec’s machine shop is entirely in-house, our tooling experts respond more efficiently and precisely to a request for change. Our tooling:

- Matches your exact design specifications, including outside and inside diameters (OD and ID), number of lumens, wall thickness and profile.

- Compensates for the effect of process conditions, including pressure, temperature and material flow rates

Our machine shop includes:

- Master CAM, which turns specifications into code and keeps generational information about previous runs

- Wire EDM (electrical discharge machine) which turns the Master CAM code into precision cuts

- Tools for maintaining Microspec’s equipment, including dryers and extruders, in peak condition

The precision of our proprietary tooling results from a collaborative effort involving Microspec’s manufacturing department; engineering and development department; and extrusion specialists.