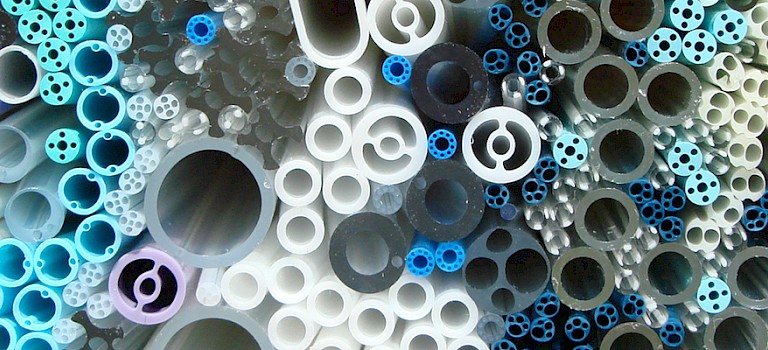

Microspec began in 1989 without permanent equipment, a permanent home or even a customer—but with a very clear vision: to become a driving force for innovation in custom medical extrusion. Now Microspec is an industry leader with a global reputation for innovation, quality and willingness to accept challenges.

We have structured our business for growth and continuous improvement. We are positioned to triple our business. We invest in innovation and we invest in our people. We ensure that the people closest to the work itself, those who understand it best, have the tools to make great extrusions consistently.

1989

Tim Steele founded Microspec Corporation.

1990

Microspec is incorporated and moves into 1200 square foot building in Jaffrey, New Hampshire.

Microspec runs first extrusion

1990

Microspec runs its first bump tube

1991

Business Triples

Microspec outgrows its original space and moves to a larger facility.

1992

Microspec exhibits at a trade show for the first time.

1993

Microspec extrudes its first coated wire: a 12-micron thick coating on a 50-micron wire; the finished outside diameter is only 75 microns (0.003 inch).

1994

Microspec designs special co-extrusion crosshead to make 2-lumen tube with 2 encapsulated radiopaque stripes, now company's longest-running product.

1994

Microspec continues to expand and moves to larger facility in Jaffrey.

1994

Microspec extrudes its first PICC bump tube.

1995

Tim Steele develops a process that maintains a constant OD for the plastic jacket over a wire with a varied OD.

1997

Microspec receives ISO 9002:1994 certification.

2002

Tim Steele receives patent 6,371,929 for "method and apparatus for producing steerable coated guidewires" with a variable OD and uniform coating.

2003

Bump tubing becomes Microspec's number one product.

Microspec receives ISO 9001:2000 certification.

2004

Further business expansion is facilitated with the purchase of 327 Jaffrey Road building in Peterborough.

2005

Microspec moves to Peterborough, expanding extrusion operations, research and administration.

2006

Microspec adds a fully equipped machine shop for custom tooling.

2007

Microspec adds a 4500 square foot dedicated research and development laboratory.

2008

Microspec is awarded a New Hampshire Job Training Fund grant to train employees in Lean manufacturing; implements first Lean cell.