Our People

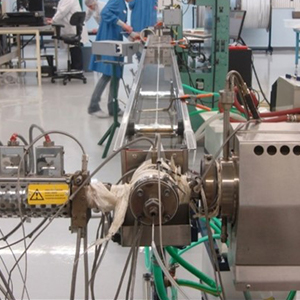

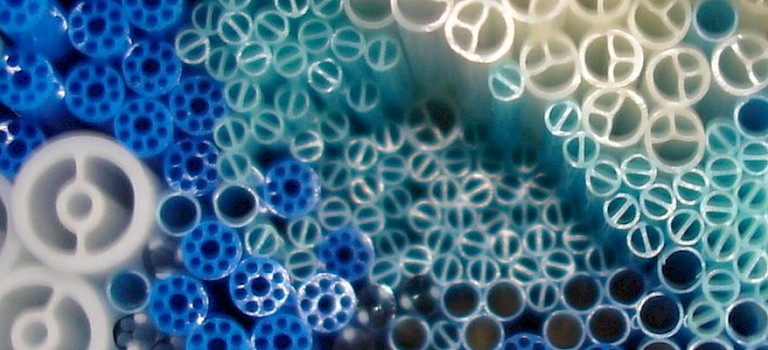

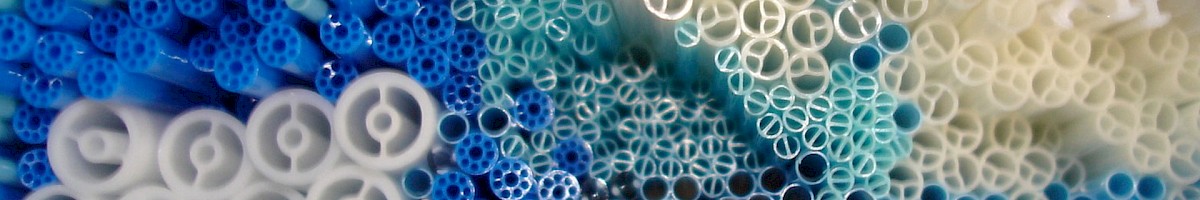

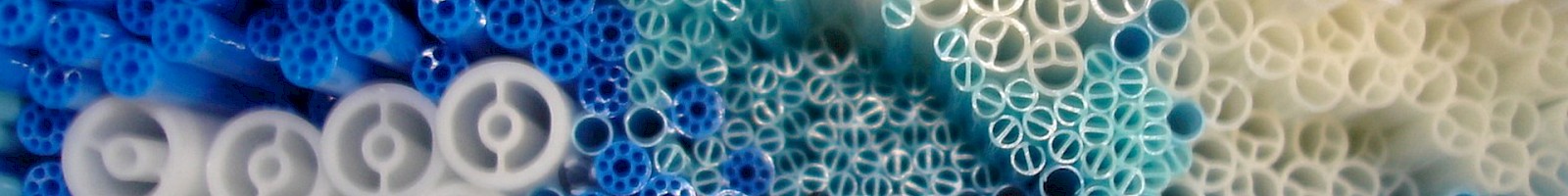

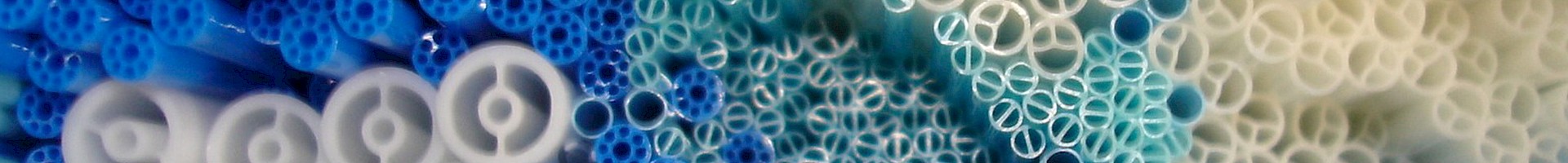

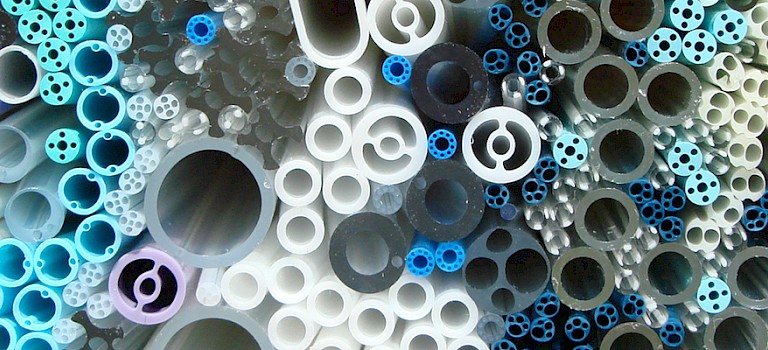

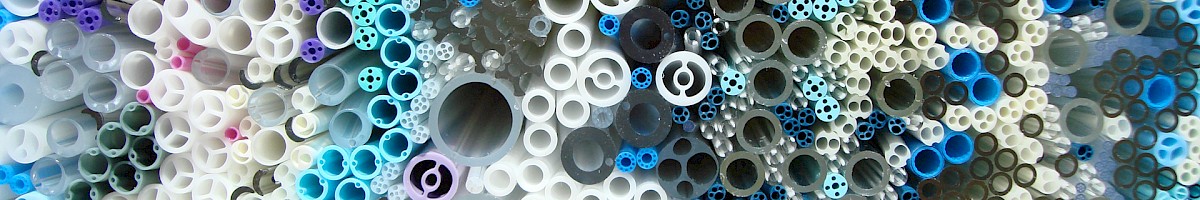

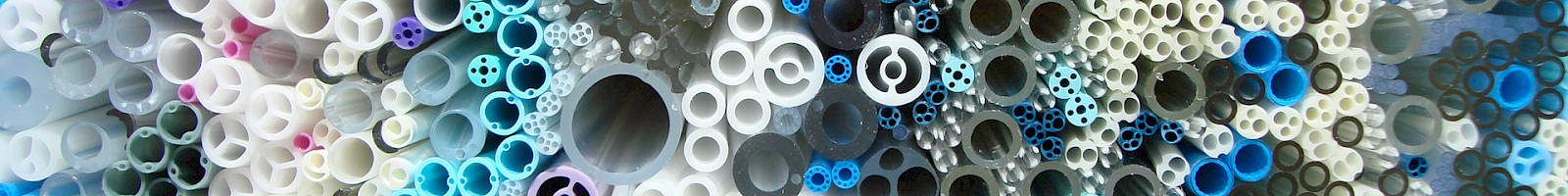

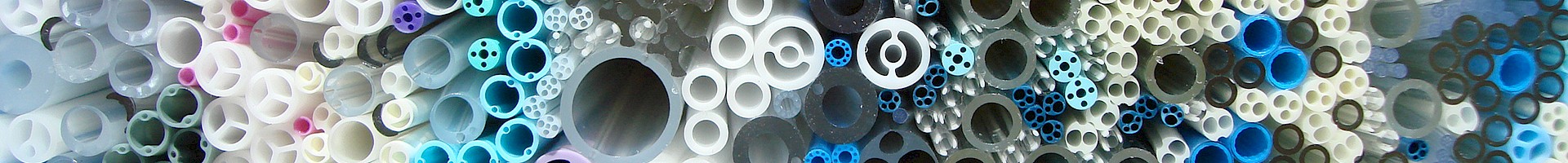

Our hand-picked, highly trained team works collaboratively with you to meet your specifications for custom medical tubing. Microspec's culture of innovation is at your service. Together, we'll help you solve your most difficult extrusion challenges.

Knowledge about extrusion materials, tools and processes runs deep at Microspec, representing more than twelve decades of experience in the extrusion and medical device industries.

We're large enough to handle the most demanding commercial runs. Yet every employee is personally committed to quality medical tubing.

Tim Steele

Founder and CEO

Tim Steele, CEO, founded Microspec in 1989 to extrude custom medical tubing that challenges the capabilities of other extrusion companies. "You have to be a visionary," he explains. "The best extrusion technicians can see in four dimensions. Microspec is tenacious when we're extruding challenging products."

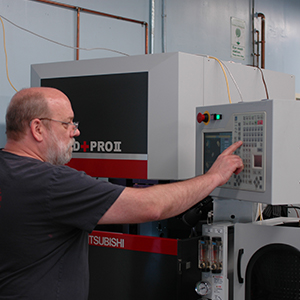

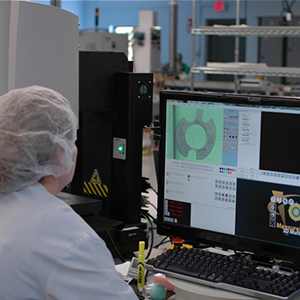

Over the years, extrusion resins, technology and processes have evolved. Microspec has managed to stay ahead of those changes in part because research, engineering, machining and manufacturing have all remained in-house. "We don't go outside for our proprietary tooling or processes, so we're more flexible and we have more control," Tim asserts. "We're proud of what we do, we're committed to the customer and we enjoy the challenge of taking on jobs other people won't. If anyone can do it, Microspec can."

After graduating from Lehigh University with a degree in history, Tim went on to graduate school. He began working part-time at Teleflex running a Teflon extruder, and quickly became technical supervisor. After a successful career at Teleflex, Tim founded Microspec. He attributes his success to two factors.

The first is his practical as well as theoretical knowledge of extrusion processes. "I began by learning the nuts and bolts of extrusion," he says. He holds a patent for a polymer jacket on a metal guidewire and was one of the first to experiment with bump and PICC tubing.

As for the second factor, Tim cites the values instilled in him as a championship distance runner. He was Lehigh University's first-ever All American distance runner, finishing in the top 15 nationally among U.S. born runners at the 1970 U.S. Track and Field Federation Championship and again at the 1972 AAU National Championship. He was invited to 1976 trials for the USA Olympic team, but was forced to withdraw because of an injury. In 2008, he was inducted into the Roger S. Penske/Lehigh Athletics Hall of Fame.

Those experiences formed his approach to teamwork at Microspec. "Only one person crosses the finish line at a time, but I was on a cross-country team that pulled each other along," he says. "At Microspec, we rely on each other. We know every operation that has to be done right to get the extrusion shipped. We're not afraid to try new things"

Tim heads a Research staff that combines decades of technical knowledge with the ability to envision new relationships between materials, processes and tooling. Microspec's global leadership in custom medical extrusions reflects Tim's research philosophy: "You can't be afraid to try new things. You have to be fearless or you miss your opportunity."

In his spare time, Tim sits on the boards of two nonprofits, the New Hampshire Dance Institute and Social Entrepreneurial Student Leadership. He also works with local schools to promote education through experiential learning for all students. He believes strongly in the power of education. "You have to share your expertise," he says. "You promote creativity with communication. Microspec continues to grow and prosper today. We have many new ideas, objectives and goals ahead. There is still so much to do."