Nylon was invented in 1931. Nylons offer corrosion and abrasion resistance, light weight, lubricity and resistance to stress and pressure. Nylon compounds are hydroscopic and therefore absorb moisture. They aren't as flexible as polyurethanes and don't bond as well.

Nylons are semi-crystalline polymers. As a result, they have a sharp melting point as well as a glass transition temperature. (By way of contrast, amorphous polymers like polycarbonates and polysulfones, do not have a sharp melting point.) Nylons lose a significant amount of their mechanical properties when heated above the glass transition temperature, depending on whether they are reinforced.

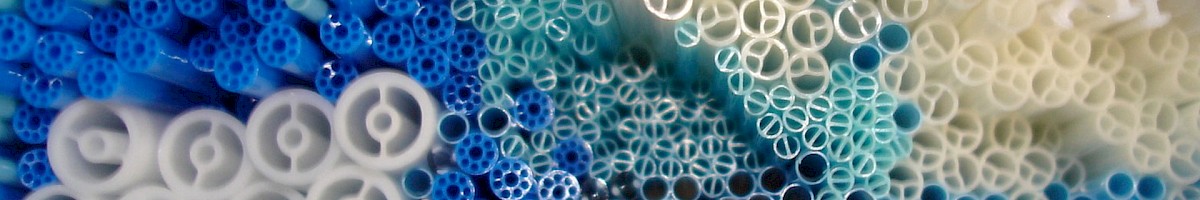

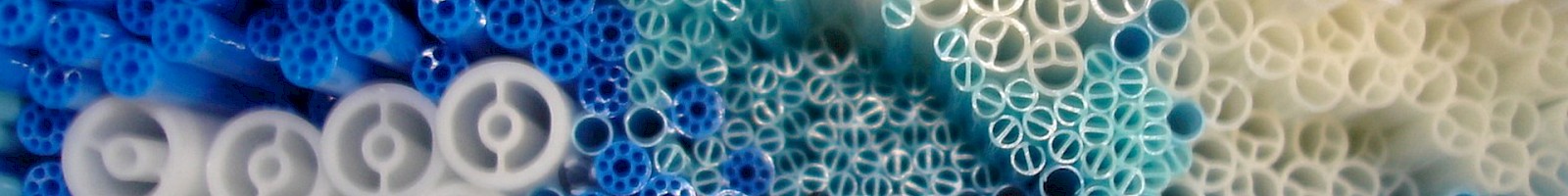

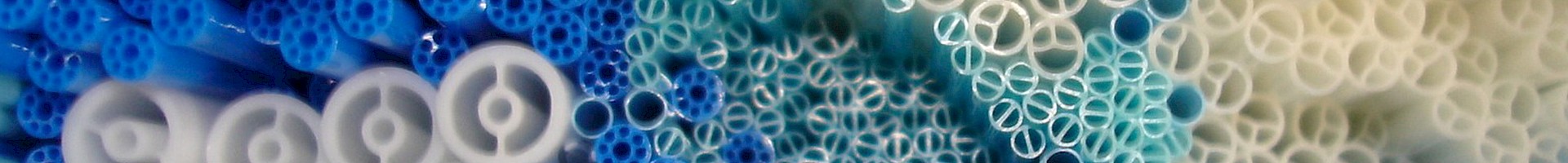

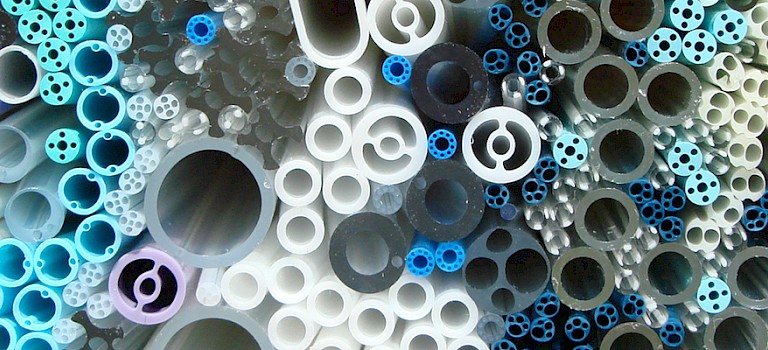

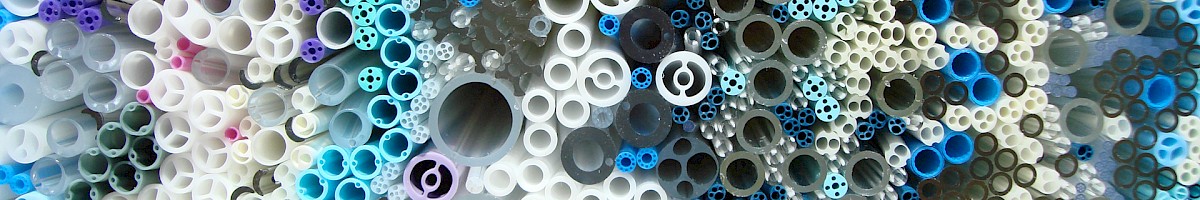

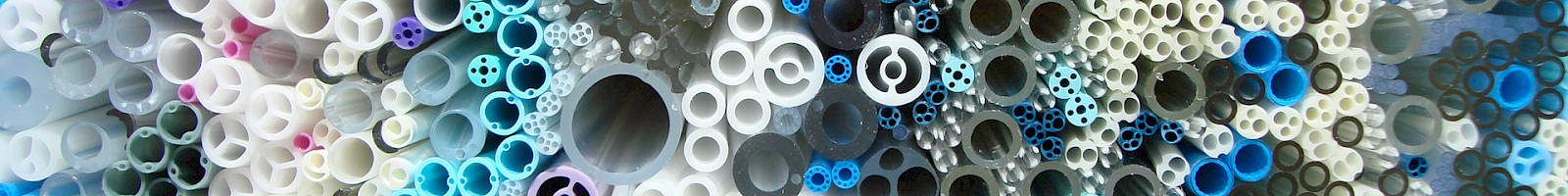

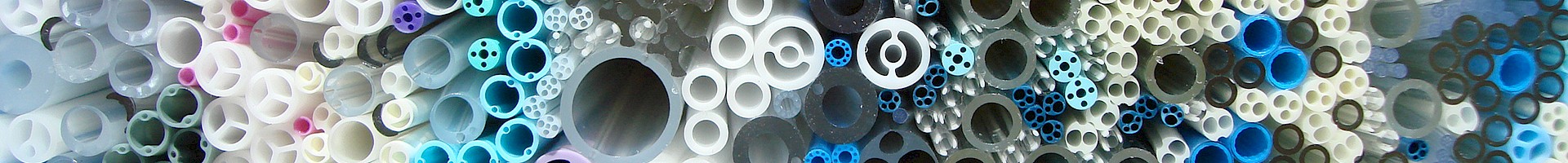

Nylon tubing may be transparent or semi-opaque. The properties of nylons make them suitable for many applications, including bump tubing, co-extrusions, striped tubing, micro-extrusions, multi-layered walls, single and multi-lumen tubing and profile extrusions.

The five main classes of nylon are nylon 6,6, nylon 6, nylon 6,12, nylon 11 and nylon 12.

Glossary Of Terms

properties

The physical and mechanical properties of a polyurethane, nylon or engineering resin depend on its chemistry, structure, chain length and bonds between chains. They can be altered by combining the material mechanically and chemically with other materials, creating a copolymer that shares some of the properties of both materials.

| Property | Measure Low | Measure High |

|---|---|---|

| Hardness | Soft | Rigid |

| Vicat Softening Point | 140°F (60°C) | 482°F (250°C) |

| Tensile strength | 2180 psi (15 MPa) | 13000 psi (89.6 MPa) |

| Elongation at break | 50% | 790% |

| Biocompatibility | May be suitable for remaining in the body as long as 30 days | |

| Sterilization | Dry heat Ethylene oxide (EtO) Gamma radiation Steam |

|

| Trade Names | Aesno Besno Nylon 6 Nylon 6,6 Nylon 12 Pebax Vestamid |

|