August 3, 2022

Released by Microspec Corporation08.03.22

By Sean Fenske, Editor-in-Chief

Getting to market quickly while saving on costs is the goal of virtually every medical device manufacturer. As such, they are seeking best practice advice from their suppliers. One suggestion is common among those service provider partners—that is, bring them into the discussion as early as possible.

When a device manufacturer involves its supplier early in the development process, a number of advantages can be realized. For projects involving extrusion, the recommendation is no different. Having the extruder involved early in development provides benefits whereas later entry can lead to costly redesigns or delays in getting to market. Optimize collaborative efforts by getting suppliers involved early.

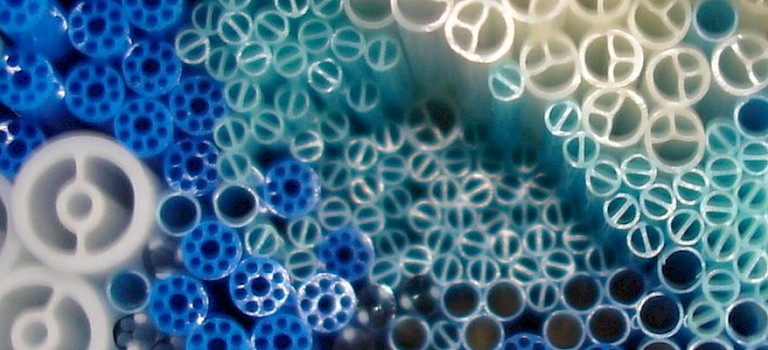

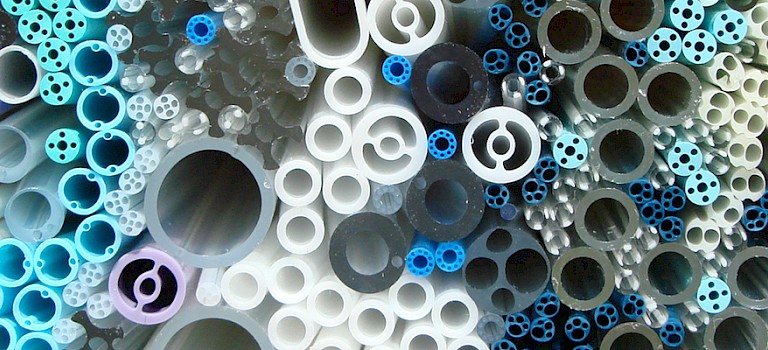

With this in mind, Tim Steele, founder and CEO of , provided insights on several specifics with regard to having the extruder involved earlier in the development process. His suggestions and best practices can help OEMs save time and money, resulting in a more successful overall product launch.

Sean Fenske: When it comes to using your contract manufacturing services, how many companies approach you after they’ve already begun the development process? How does this limit your effectiveness?

Tim Steele: It used to be that everyone had already initiated development of the device prior to contacting the extruder of the part and this is still the case outside the USA. However, within the USA, it is becoming common to be contacted by the device manufacturer at the concept stage in order to avoid design flaws in the extruded tube, which saves time and money and helps get the device to market faster.

Fenske: What are the primary advantages of engaging the contract manufacturer early in the development process or at the start of design?

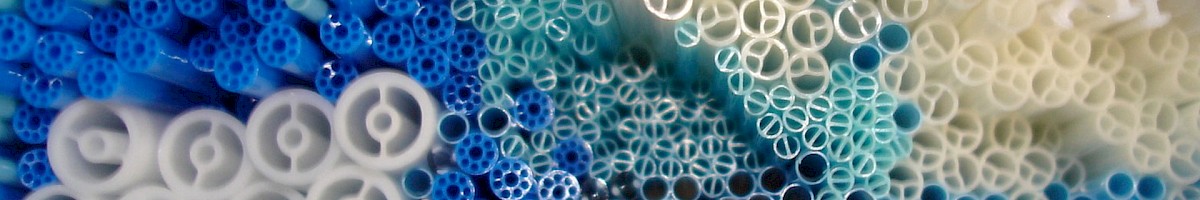

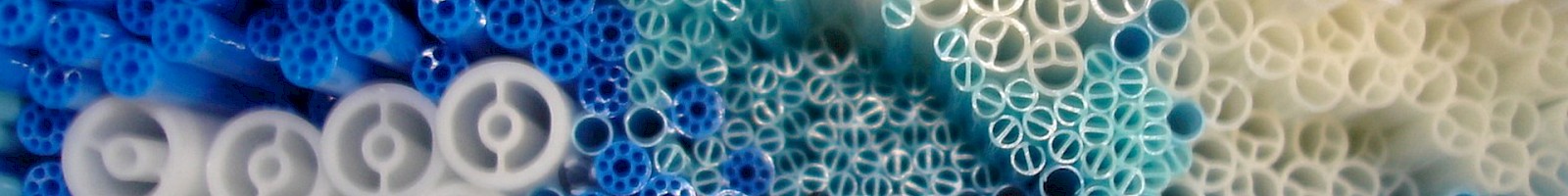

Steele: Contacting the contract manufacturer early helps get a project on track faster. Many consider extrusion of a complex part “black magic” and contacting the extruder at concept enables the device maker to learn what will and will not work before initiating design of a part. This can save months of extrusion development!

Fenske: Can early engagement have an impact on the regulatory process and the timeline of that stage?

Steele: Early engagement of the contract manufacturer does positively impact the regulatory process and the timeline as the validation of the process is a focus from the start. Aligning the manufacturability and process capability of the extruded component with the CTQ (critical to quality) and functional intent of complex parts keeps the development focused on producing a capable and functioning part and streamlines the validation of the extruded component. The importance of having a validated extrusion process cannot be overstated.

Fenske: What advantages are realized from engaging the contract manufacturer earlier that most device manufacturers don’t even consider?

Steele: What those device makers fail to consider by pre-designing a part before contacting the extruder or contract manufacturer is the time that can be saved with early engagement of the contract manufacturer. Lots of re-designing can be avoided.

Fenske: As the contract manufacturing partner, do you encourage all the supply partners to also be involved such as the material provider and/or a sub-assembly company?

Steele: Involving all supply partners as early as possible is an important practice in order to avoid mistakes and development of a mutual understanding of all expectations with the process being undertaken.

Fenske: Do you have a success story you can share that helps illustrate the real value of engaging with the contract manufacturer earlier in design?

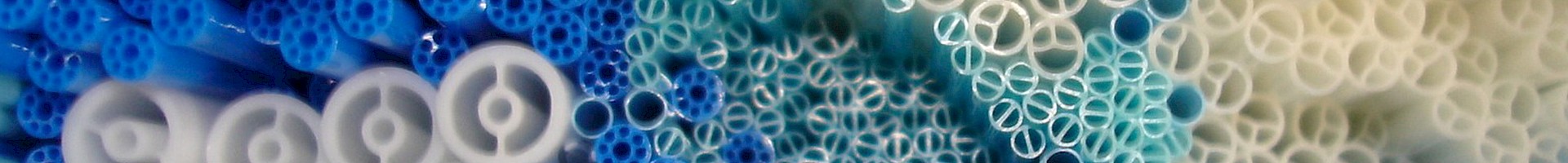

Steele: MicroSpec has several success stories of early involvement with a client. The number one story involved working with CR Bard in developing a new family of PICC catheter bump tubes. MicroSpec worked very closely with the Bard engineering team and, in a period of less than four years, Bard became the number one PICC manufacturer in the USA!