April 28, 2021

Released by Microspec Corporation 04.28.21

By Sean Fenske, Editor-in-Chief

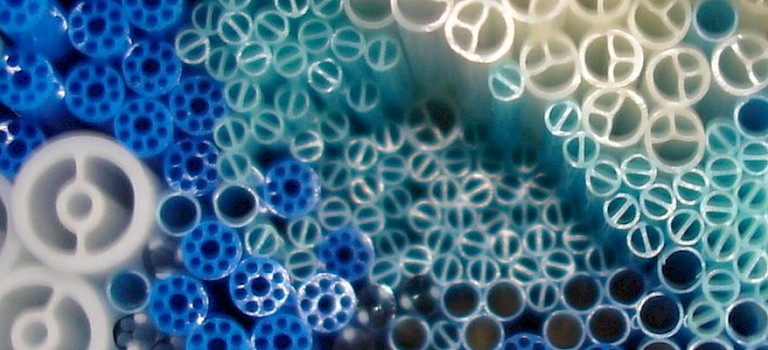

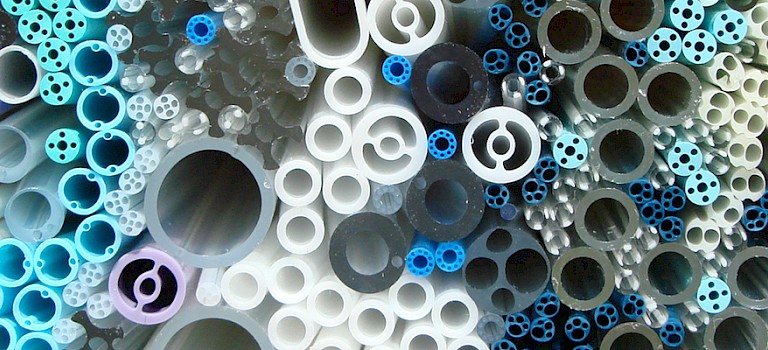

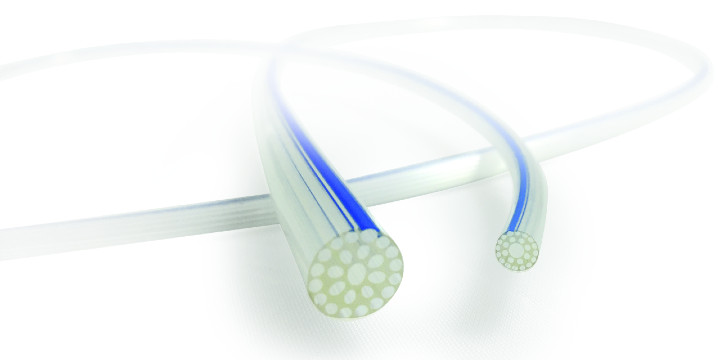

Proximal 0.105 inch/Distal 0.08 inch bump tube

Medical devices have been on a trajectory that has them getting ever smaller. As a result, the components within them must similarly reduce in size and take-up a smaller footprint in the overall design of the product. The tubing involved in a device is not an exception to this rule. In fact, while the device is getting smaller, functionality is often increasing, which means more things could be traveling through that tubing. One solution for meeting the requirements of both factors is the use of multi-lumen tubing.

Multi-lumen tubing enables disparate media to be transferred through it without risking cross contamination. While both gases and liquids can travel through the lumens, other devices require electrical wiring to also be contained within the tubing, such as for minimally invasive surgical instrumentation. As such, designers are developing devices that call for multi-lumen tubing to be used without always knowing the primary factors to consider.

With this in mind, Tim Steele, founder and owner of —a firm that has established a global reputation for extruding some of the smallest, most complex, and tightly toleranced medical parts in the industry—shared his expertise on a number of topics around multi-lumen tubing. In the following Q&A, Steele offers insight on common challenges he sees, the importance of working early with a trusted supplier, and the important aspects of the materials used.

Sean Fenske: For how long has multi-lumen tubing been used in medical devices?

Tim Steele: Extruded multi-lumen tubing for medical applications has been around for many decades. For vascular access, one of the first designs was the standard Double D. Another early multi-lumen tube was the triple lumen—a smiley-faced tube. Interestingly, both of these early multi-lumen designs are common profiles still used today.

Use of multi-lumen tubing has grown with medical technology, continues to grow today, and will continue to do so as long as doctors need to access the body to deliver drugs or perform procedures. Multi-lumen tubing is closely related to extruded medical profile tubing, which utilize the same extrusion technologies as multi-lumen. Common applications include surgical devices and, with advancements in robotics, both multi-lumen and extruded medical profile tubing can be expected to experience significant growth.

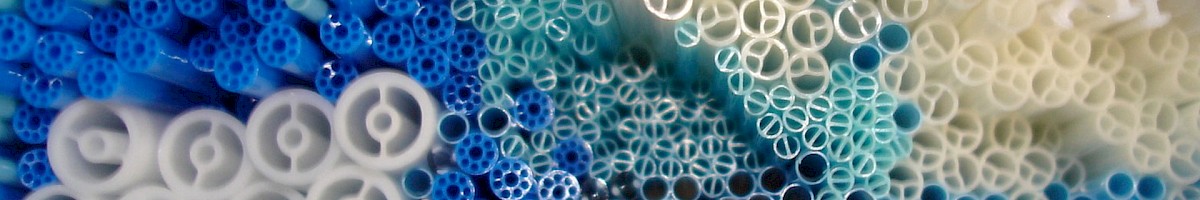

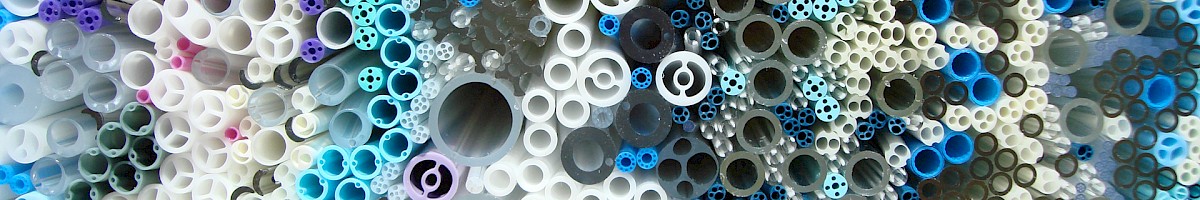

A 25-lumen co-extruded bump tube

Fenske: When requiring a multi-lumen tube, why is it so important to engage a supplier early?

Steele: Complex, multi-lumen tubing presents a wide variety of extrusion challenges not encountered when extruding basic, single-lumen tubing. As such, it is important to engage the extruder early to discuss the form, fit, and function of the multi-lumen tube with regard to the anticipated challenges in extruding the tube.

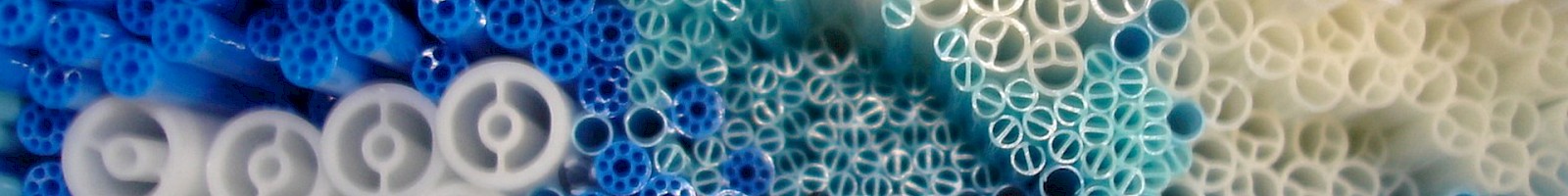

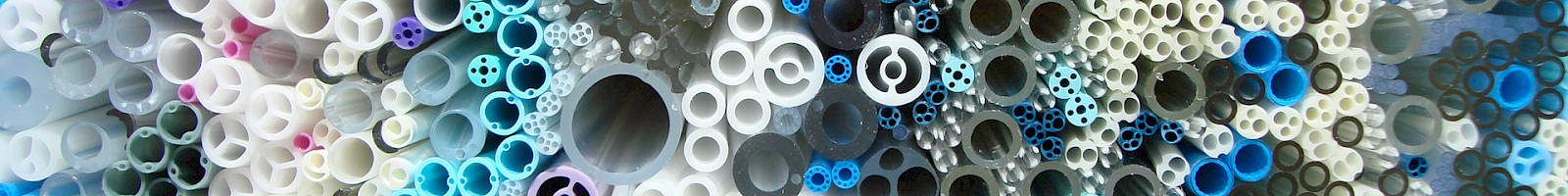

Tri-extruded multi-lumen with Helical Twist

In a first discussion with the extruder, the OEM should have already executed a mutual non-disclosure agreement as both parties will be disclosing varying degrees of proprietary information. The OEM should also have a concept drawing of the tube and be prepared to discuss all aspects of the proposed design, including raw materials. In addition, the OEM should be open to recommendations from the extruder as the extruder probably has valuable experience extruding similar parts out of the same raw material. The main object of these early discussions is for both parties to understand all the aspects of what it will take for product realization. A great question for the OEM to ask is, “How many attempts will this part require to get it right?” Getting a multi-lumen tube finalized in a timely way is best accomplished by understanding the challenges up front and early involvement of the extruder is key to this.

Fenske: What are the most common challenges associated with multi-lumen tubing?

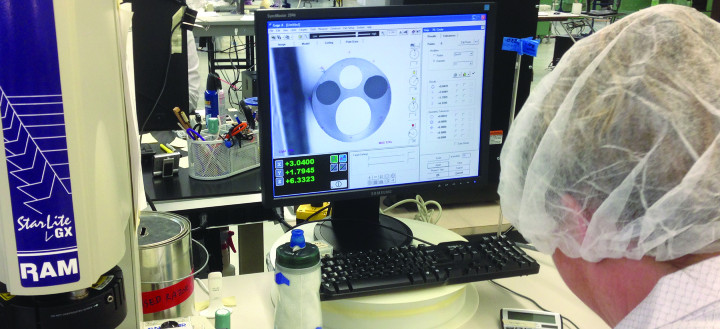

Steele: The most common challenges I have found are interior wall thicknesses and specified geometric shapes. In complex, multi-lumen tubing, getting plastic to flow in areas deep within the geometry of a tube design is a challenge to all extruders and the technology behind die and tip design is customarily guarded as a trade secret.

Fenske: When it comes to identifying the right material for a multi-lumen tube, what are some considerations for the designer to think about?

Steele: As with any medical tube, material selection is a critical decision as it not only directly affects function of the catheter, or device, but the material must also be processable in extrusion. In selecting the appropriate material, the design engineer needs to consider much more than the function of the catheter or device. Dynamic flow characteristics of the melted polymer are critical to any multi-lumen tube: melt strength; draw down characteristics; thermal stability; tactile characteristics (is it sticky or lubricious?); soft or hard polymer; hygroscopic characteristics; level of gel content; and, depending on the application, the list of considerations goes on. Ultimately, the appropriate material must be processible according to the extrusion process utilized.

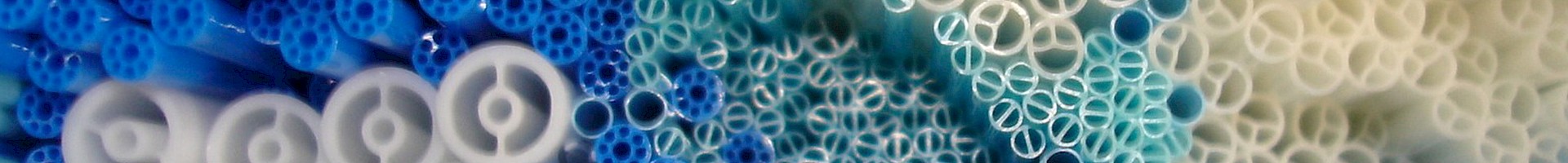

A 5 French co-extruded two-lumen tube with two stripe

Fenske: Speaking of materials, what are some of the common challenges you encounter with them as related to multi-lumen tubing?

Steele: Lot-to-lot variability of the raw materials is certainly a challenge and especially so with polyurethanes. Multi-lumen extrusion is very sensitive to changes in viscosity and melt flow index (MFI). For example, it is not unusual for tools that produce a perfect tube from material with an MFI of 9 not to work at all with the same material from a different lot that has an MFI of 3. So MFI and viscosity are dynamic values multi-lumen extruders pay close attention to and, when validating an extruded part, the extruder will define and specify an acceptable range that works.

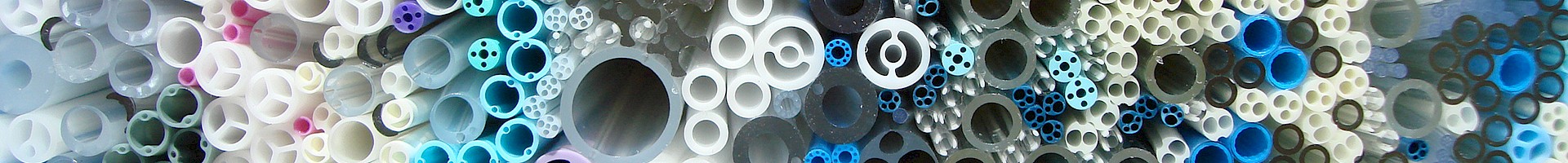

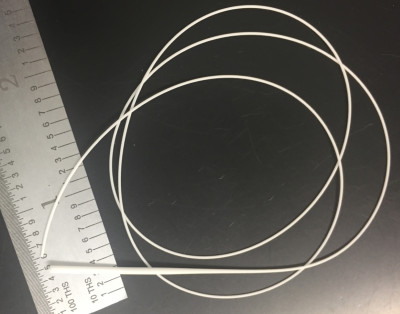

A 1.9 French two-lumen micro-tube

Related to these complex geometries is the challenge that the tube is required to precisely match a second tube with the same geometry, but a different durometer. The assumption that the tools that produced the proximal end of the tube will also make the softer, distal end can be a time consuming and costly error if the extruder discovers the same tools will not produce the same geometries from two different durometers of the same raw material. In this situation, the extruder must then go back and re-design tools to address the issues of the different flow characteristics of the two resin durometers.

Fenske: Do you encounter issues with a designer indicating too many or too large of lumens for the proposed overall tubing size? Does the math sometimes simply not work?

Steele: A common mistake made in designing and specifying multi-lumen tubes is not having the dimensional value of the tube add up, which is generally referred to as stacking up. For decades, device designers have been confronting the challenge of size, striving to make a part as small as possible while also optimizing functionality. In doing this, the practical limits of the materials, the extrusion process, and the extrusion tools are pushed, and the proposed design all too often fails to address the need for dimensional tolerances. When these tolerances are added back into the tube design, the tube is too big—it does not stack!

Stacking issues most commonly occur when a design integrates a combination of different geometric shapes, minimum cross-sectional areas of lumens, and minimum wall thicknesses. This can lead to a serious problem of over-specifying.

Multi-lumen and profile tubes have many overlapping characteristics.

Over-specified tubes present a particular problem to the extruder and the OEM. When it comes time to validate the new part for production, the specified tolerances may be so tight that any variation in extruded product (even if within the specified tolerances) will produce resulting data that indicates the extrusion process is not capable. This marks a dead end to validation. It is important to be mindful of over-specifying.

Fenske: Before we wrap up, would you like to share any thoughts or comments about any of the topics discussed?

Steele: The multi-lumen segment of the industry is a dynamic part of medical extrusion. Through advancements in medical technology and integration with other extrusion technologies, multi-lumen extrusion continues to expand. Innovation is a key force in multi-lumen development and to make the most of working with a multi-lumen extruder, the OEM should listen to the extruder and share functional concepts of the new device.